Description

Vertical pressure leaf filters are an important piece of equipment used in various industries for the filtration of liquids. They are specifically designed to remove impurities and solid particles from liquids as part of the manufacturing and processing of products. This comprehensive filtration system efficiently separates solid-liquid mixtures and is widely utilized in industries such as oil, chemical, pharmaceutical, and beverage production.

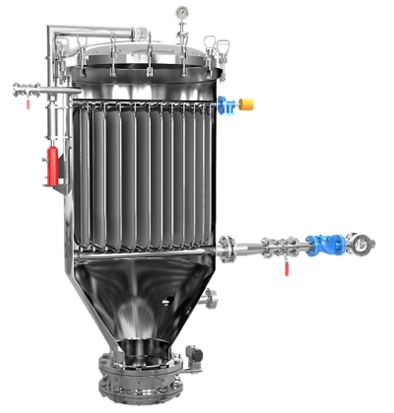

The design of a vertical pressure leaf filter typically consists of a vertical cylindrical vessel housing several vertically mounted filter elements, commonly referred to as filter leaves. These filter leaves are the key operational components of the filter system and are structured to effectively capture solid particles and impurities present in the liquid being filtered. The enclosed design of the filter ensures a closed and controlled filtration process.

The operation of a vertical pressure leaf filter begins with the introduction of the unfiltered liquid into the vessel. The liquid flows through the filter elements, and the solid particles are captured, allowing the clean liquid to exit the system for further processing or use. The captured solid particles form a filter cake on the filter leaves, and the clean liquid, also known as the filtrate, is collected and drained out of the filter vessel.

The construction and materials used in these filters are carefully selected to withstand the pressure differentials and operating conditions. Often, the filter leaves are made of perforated metal sheets or woven wire mesh that allows for effective filtration of the liquid. The design of the filter is such that the captured solid particles form a dense filter cake, which helps to improve the filtration efficiency and prolong the life of the filter leaves.

One of the key advantages of vertical pressure leaf filters is their ability to handle high flow rates and large volumes of liquid with efficiency. This makes them suitable for industrial applications where a continuous and robust filtration process is required. In addition, the design of these filters allows for easy maintenance and cleaning, making them a practical and reliable choice for industrial filtration needs.

Furthermore, vertical pressure leaf filters are known for their versatility and adaptability to a wide range of applications. They can be used for filtering various types of liquids, including oils, chemicals, syrups, and pharmaceutical solutions. The filters can be customized to accommodate specific requirements, ensuring that they effectively meet the unique filtration needs of different industries and processes.

In terms of operating principles, vertical pressure leaf filters can operate in either a batch or continuous mode, depending on the specific application and production requirements. In batch operations, the filter vessel is filled with unfiltered liquid, the filtration process occurs, and then the filtered liquid is drained. In continuous operations, the filter system maintains a constant flow of liquid, allowing for uninterrupted filtration and collection of the filtrate.

When it comes to maintenance and cleaning, vertical pressure leaf filters are designed to facilitate easy access to the filter leaves for inspection and replacement, if necessary. This ensures that the filtration system can be properly maintained, thereby extending its operational life and sustaining its efficiency over time.

In conclusion, vertical pressure leaf filters play a crucial role in the industrial filtration process, providing an efficient and reliable means of separating solid particles from liquids. Their robust design, high flow capacity, and adaptability to various applications make them a valuable asset in industries where the purity of liquids is of utmost importance. Whether in the production of edible oils, pharmaceuticals, or chemicals, vertical pressure leaf filters contribute significantly to maintaining the quality and integrity of the final product.

Reviews

There are no reviews yet.