Description

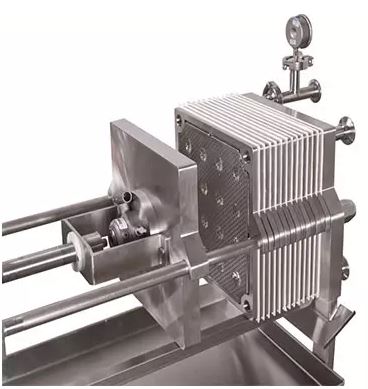

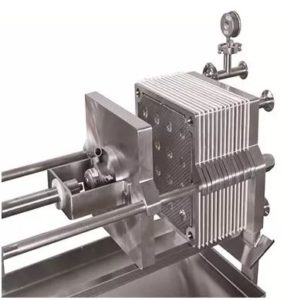

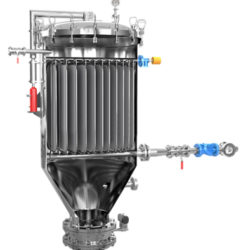

Custom filter press for polishing up any Oleoresins dissolved in a solvent.

Basic Pricing as follows:

B) Catch Tray

C) Add Automatic Hydraulics

D) Add Wheels

E) Add Automatic Pump Controls

F) Add Pump Mount

Your oleoresin must be dissolved in a solvent like ethanol, isopropanol, and methanol. We do not recommend more volatile solvents on this unit such as pentane, or hexane.

Further clarification and decontamination is achieved by using a silica based medium and lab grade filter papers to produce a tincture that is as clear as possible which has been scrubbed of dirt and debris, mold and bacteria, most color from chlorophyll and other contaminants, heavy metals from fertilizers, and some chemicals from pesticides.

- Labor savings.

- Solvent savings.

- Time savings.

- Safe and easy to use.

- Quick and easy to clean.

- We stock all consumables at reasonable prices.

- Multi-function unit.

- Fast filtering.

- Made in the USA

- Can Filter, de-wax, bleach, deodorize, and clarify.

- After extraction with solvents, filter out debris.

- If working with gas extracted material, dilute in solvent and freeze. Freeze solution and run through filter for de-waxing.

- Degum your solution and remove gums. (Not with this machine)

- Filter with clay.

- Filter with carbon.

- Filter with silica.

- Proceed to Rotovap and SPD, Wiped/Thin Film etc…

Your pump can be customized to operate on the temperature based on your application. Below are the diaphragm materials and their recommended operating temperatures.

Geolast®: 10°F to 180°F (-12C to 82C)

EPDM: -40°F to 280°F (-40C to 138C)

Santoprene®: -40°F to 225°F (-40C to 107C)

Viton® (FKM): -40°F to 350°F (-40C to 177C)

PTFE: 40°F to 220°F (4C to 104C)

Polyethylene: 32°F to 158°F (0C to 70C)

Polypropylene: 32°F to 180°F (0C to 82C)

PVDF: 0°F to 250°F (-18C to 181C)

Nylon: 0°F to 200°F (-18C to 93C)

Manufacturing times vary. Shipping will be invoiced separately.

Reviews

There are no reviews yet.