Production Extraction Plants

ProExtractions offers a wide variety of extraction production lines to meet the tightest requirements. Our systems are designed for high throughput, minimum waste, safety, and repeatability.

Our control systems integrate to all of the production processes. They can act independently or be centralized and networked.

Mixing tank designs are available and customizable. We incorporate pumps and valves for process flow and transfers.

We manufacture tanks for various purposes includingmixing, blending, carbonation, and storage.

We manufacture Augers / Conveyor for various material conveying requirements.

Our control systems integrate to all of the productionprocesses. They can act independently or be centralizedand networked.

Distillation / Falling Film Evaporators / Wipe Film Evaporator systems for solvent recovery and extraction.

Full Process Automation

ProExtraction offers a full range of control solutions for your processes. Plant wide or individual process control technology is our specialty.

An integrated automation package is critical for a production line for maximized efficiency. Our control packages are designed for increased production, a high level of repeatability, quality control, safety, and labor reduction.

Designed and programmed for your process requirements.

Our panel shop is UL and cUL certified. We are also certified for hazardous locations.

Intrinsic circuit designs for components inside C1D1, C1D2, ATEX, IEC environments.

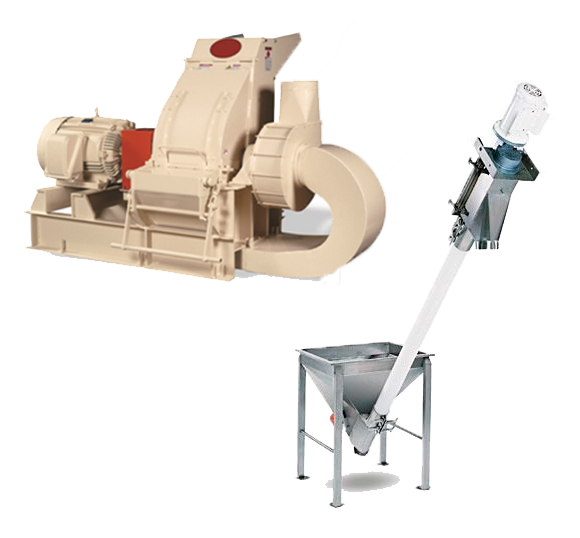

Material Conveying

ProExtractions offers a wide variety of extraction production lines to meet the tightest requirements. Our systems are designed for high throughput, minimum waste, safety, and repeatability.

An integrated automation package is critical for a production line for maximized efficiency. Our control packages are designed for increased production, a high level of repeatability, quality control, safety, and labor reduction.

Designed for milling many materials including HEMP and other cannabis products.

Bulk storage and bulk unloading

Ideal for loading material into a mixing tank or moving milled material to astorage tank

Explosion proof designs when applicable

Mixing Tanks

ProExtraction manufactures a variety of stainless-steel mixing tanks. You can choose from our standard designs or have us build your tank to your specifications. Typical uses are for solvent extractions and batch mixing.

Grade 316L stainless steel offers a higher level of corrosion resistance. It is a necessity when working with high proof ethanol extractions.

Explosion proof mixing motors are available. These motors are necessary when working with high proof ethanol extractions or powders that are combustible.

Entry ports are placed on the tank to accept conveyed materials such as milled Hemp. We also include ports for vacuum pressure relief valves, andliquid and solvent entry points. CIP (Clean in Place) ports are also installed in the tank to connect to the internal spray balls. Bottom ports are designed for complete tank discharge.

Filtration Presses

For solvent extractions such as ethanol, the maceration process uses ground-up plant material (such as hemp). This bio-mass is then mixed so the solvent strips the oil out of the plant fibers. For hemp, this is CBD oil. The hemp oil/solvent is then run through a filter press to separate the biomass from the oil/solvent mixture. Our filter presses can be set up to filter down to 1 micron.

Storage Tanks

Our storage tanks can be manufactured in a variety of configuration. These tanks are used for liquid and slurry storage. They can also be utilized for feedstock, finished products whether they are heated or refrigerated tanks.

Grade 304L or 316L stainless steel, we offer a higher level of corrosion resistance. It is a necessity when working with Hexane or high proof ethanol extractions. The RA readings internall and externally provide a low bacteria and sanitary environment.

Ports for vacuum pressure relief valves, and liquid and solvent entry points. CIP (Clean in Place) ports are also installed in the tank to connect to the internal spray balls. Bottom ports are designed for complete tank discharge.

Sample valves can be placed on the tank sidewall and/or Low points. These are used for in process testing to maintain high quality control and standards.

Winterization & Dewaxing Processes

ProExtractions offers a wide variety of extraction production lines to meet the tightest requirements. Our systems are designed for high throughput, minimum waste, safety, and repeatability.

Pro Extractions has partnered with several chiller manufacturers. We integrate these chillers into our processes with options to cool down to -80C.

In-line winterization and dewaxing processes are implemented using cooling exchangers.

Plate filters are used for in-line separation of the lipids and waxes utilizing specialized filter media.