Description

Introduction of the scraper type wiped film evaporator

The rotary scraper type film evaporator is a kind of new high-efficiency evaporator that carries out falling film evaporation under vacuum through forced film forming by rotary scraper. With such features as high heat transfer coefficient, high evaporation intensity, short flow passing time and high operating elasticity, it is especially suitable for evaporation, concentration, degassing, precipitation, distillation and purification of heat sensitive materials, materials of high viscosity, materials easy to crystallize and materials containing granules. It is widely applied in chemical industry, petrochemical industry, medicine, fertilizer, daily chemicals, food, fine chemical industry, etc.

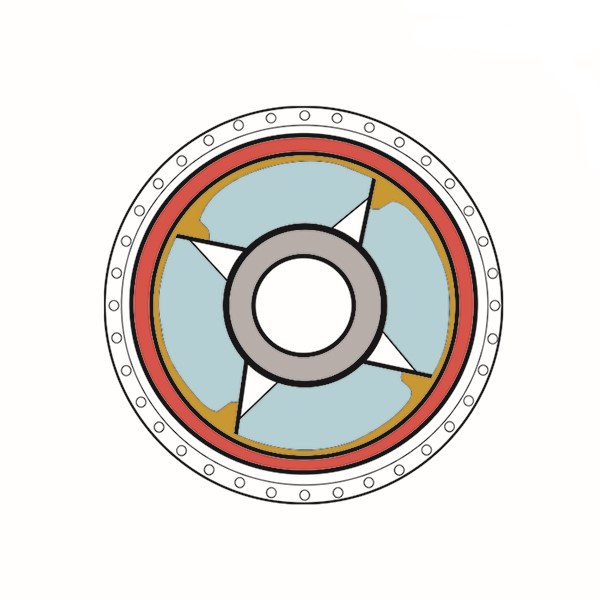

structural features of the scraper type wiped film evaporator

Motor and speed reducer.

It is the driving unit for rotor rotation. The rotating speed of rotor depends on the form of scraper, material viscosity and inside diameter of evaporating cylinder. The selection of a suitable linear speed of the scraper is an important parameter to guarantee stable and reliable operation of the evaporator and satisfactory evaporating effect.

Separating barrel

The materials enter the evaporator through the inlet at the bottom of the separating barrel and are continuously and evenly distributed on the evaporating cylinder by the material spreader installed inside the separating barrel. The secondary steam evaporated from the evaporating cylinder rises to the separating barrel. After passing through the gas-liquid separator inside it, the liquid drops or bubbles that may be carried by the secondary steam are separated, and the secondary steam will be discharged out of the evaporator from the outlet at the top.

The reasonable design of the separating barrel based on the calculation of resistance inside the evaporator is one of the key factors that avoid ” Short circuit” Of materials. (The so-called ” Short circuit” Means that the materials leave the evaporator at the secondary steam outlet before the evaporation process is completed).

Material spreader

The material spreader is installed on the rotor. Through reasonable design, the materials entering the evaporator from the tangent direction are continuously and evenly spread on the evaporating surface by the rotary material spreader.

Gas-liquid separator

The rotary vane type gas-liquid separator is installed at the top of the separating barrel. It is used to collect liquid drops or bubbles that may be carried by the rising secondary steam and make them drop back onto the evaporating surface.

Evaporating cylinder

It is also called heating cylinder. It is the evaporating surface where the materials that are subject to forced film forming by rotary scraper and the heating media inside the jacket carry out heat exchange. The inside diameter and length of the evaporating cylinder are determined by the evaporating area and appropriate length-diameter ratio.

Rotor

The rotor installed inside the evaporating cylinder is composed of rotary shaft and rotary bracket. Driven by motor and reducer, the rotor drives the scraper to make circular motion. The rotary bracket is made of stainless steel precision castings, so that its strength, geometrical dimensions, stability, etc. Are effectively guaranteed

Scraper

Due to the movement of the scraper, the materials are constantly scraped into films on the evaporating surface, so as to achieve the effect of film evaporation. According to material viscosity, the following three kinds of scraper forms are available for selection:

Sliding scraper

The sliding scraper is the most basic and common scraper form. The scraper is installed inside the four scraper guide grooves of rotor. Under the effect of centrifugal force due to rotor rotation, it is radially thrown to the inner wall of the evaporating cylinder, and make circular motion together with the rotor. This scraping of the scraper makes the materials under the status of membranous turbulence on the evaporating wall and greatly enhances heat transfer coefficient. In addition, the continuous scraping can effectively avoid the occurrence of overheating, dry wall, scaling, etc.

Generally, the scraper adopts filled PTFE. It is suitable for a working temperature of lower than 150°C. When the evaporating temperature is higher than 150°C, carbon fiber shall be adopted. The end machining of the scraper is provided with liquid guide groove of certain angle.

Fixed scraper

The fixed scraper is made of metal materials. It is rigidly connected with the rotor. The length of the scraper is the same as that of the evaporating cylinder. The interval between the rotary scraper and the inner wall of evaporating cylinder is only 1-2mm. Higher machining and installation precision is required. It is suitable for evaporation, concentration, precipitation and purification of materials of high viscosity and those easy to produce bubbles.

Hinge scraper

The scraper is suitable for materials that easily form scaling on the heating surface. The scraper is generally made of metal parts. The scraper is installed on the rotation bracket by adopting the flexible hinge. When the rotor turns, under the effect of centrifugal force, the scraper is tightly pressed at the inner wall of evaporating cylinder, and slides at certain angle (with the wall) to scrape the materials into films, and scaling on the wall is avoided.

Bottom head

The individually designed W model bottom head is provided with the high temperature resistant self-lubricating bearing, which not only facilitates material discharging, but also makes maintenance and servicing of bottom bearing convenient.

Reviews

There are no reviews yet.